Smelter Process Engineer

![[title]](https://pim.heraeus.com/images/HRD/HER_EB_Job-Ad-Header_HPM_EN_innovating_2375x950px.jpg) |

About Heraeus

Making displays foldable? Helping hearts beat with medical innovations? Or breathing new life into precious metals? As a family-owned global technology group we help our customers to always being one step ahead.

About Heraeus Precious Metals

With more than 350 years of experience in precious metals processing, Heraeus Precious Metals is the world's leading provider of innovative products and services, such as precious metals trading and recycling. Our products are used in a wide range of industries, for example to reduce climate killers such as nitrous oxide and methane and in the form of pharmaceutical ingredients for the treatment of cancer.

Our innovative strength is driven by our 3,000 employees in more than 15 countries, who work passionately with our partners to develop pioneering and sustainable solutions.

We are aware of our responsibility towards people and the environment and have set ourselves ambitious CO₂ targets. Sustainability is at the heart of all our business activities.

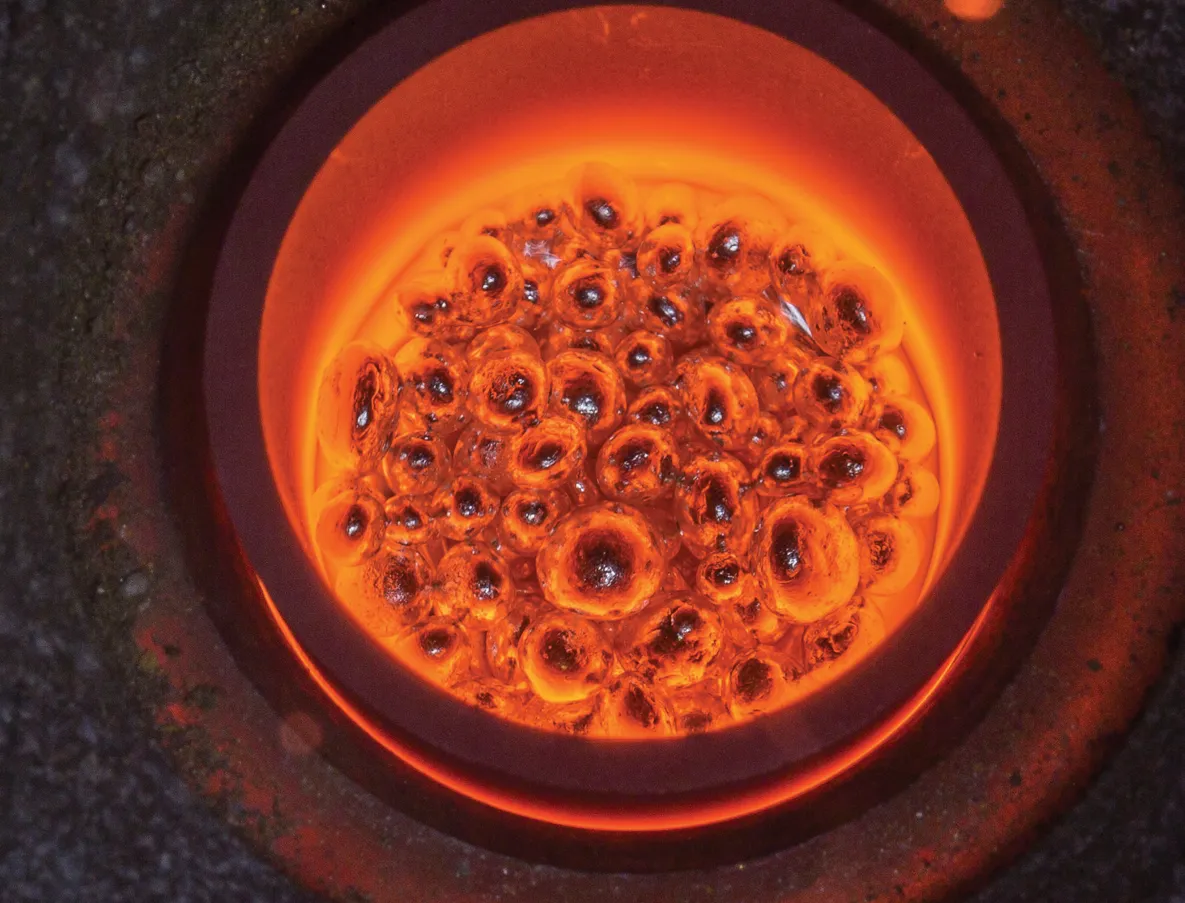

Smelter Process Engineer

The Shift Engineer is responsible for supervising the operation of a large electric arc smelter, overseeing the shift leads, and ensuring operational excellence and safety during their designated shifts. This role acts as a critical link between the shift team and higher management, specifically reporting to the Furnace Manager.

Your Role & Responsibilities:

- Oversee and manage the operation of the electric arc smelter.

- Conduct routine checks and maintenance to prevent and address mechanical and electrical anomalies.

- Take swift and decisive action in implementing corrective measures to ensure continuity and efficiency of the smelting process.

- Serve as the senior point of communication for shift members, addressing concerns, and facilitating effective information flow between management and the shift team.

- Promote and ensure the adherence to safety protocols to minimize risks and accidents.

- Identify training needs and opportunities for team members to enhance skills and performance.

- Initiate and lead continuous improvement projects to enhance operational efficiencies and cost-effectiveness.

- Inspect work areas to maintain cleanliness, safety, compliance with environmental standards.

What is required for this role:

- Bachelor’s degree in Engineering (Mechanical, Electrical, or related field).

- Proven experience in managing large-scale industrial operations, preferably in smelting or a related heavy industry.

- Strong leadership skills with the ability to manage and motivate diverse teams.

- Excellent problem-solving, organizational, and communication skills.

- Ability to respond effectively to emergencies and high-pressure situations.

-

Featured Jobs

Related jobs

- Warehouse Assistant Cartago, Costa Rica Warehouse Assistant

- Sintering Operator (WE) Chandler, United States Sintering Operator (WE)

- CMI Buford, United States CMI

- CMI Buford, United States CMI

- Human Resources Generalist Saint Paul, United States Human Resources Generalist

Related Content

-

What drives us

Innovations are part of our DNA.

-

Who we are

Our actions have been aimed at future generations since 1660.

-

Our Stories

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrudx

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

What we do

Our expertise revolves around materials.

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Careers at Heraeus: Great reasons to start your job

Discover your career opportunities at Heraeus. Learn why Heraeus is a secure and attractive employer for starting your career.

-

Career entry? Yes!

You’re looking forward to the future. So are we. Start your journey with us!

-

Work experience? Yes!

The Heraeus team wants to move forward. So do you. Discover our job opportunities!