Maintenance Mechanic (Electro-Mechanical/Automation) 2nd Shift

![[title]](https://pim.heraeus.com/images/HRD/HER_EB_Job-Ad-Header_US_EN_working_2375x950px.jpg) |

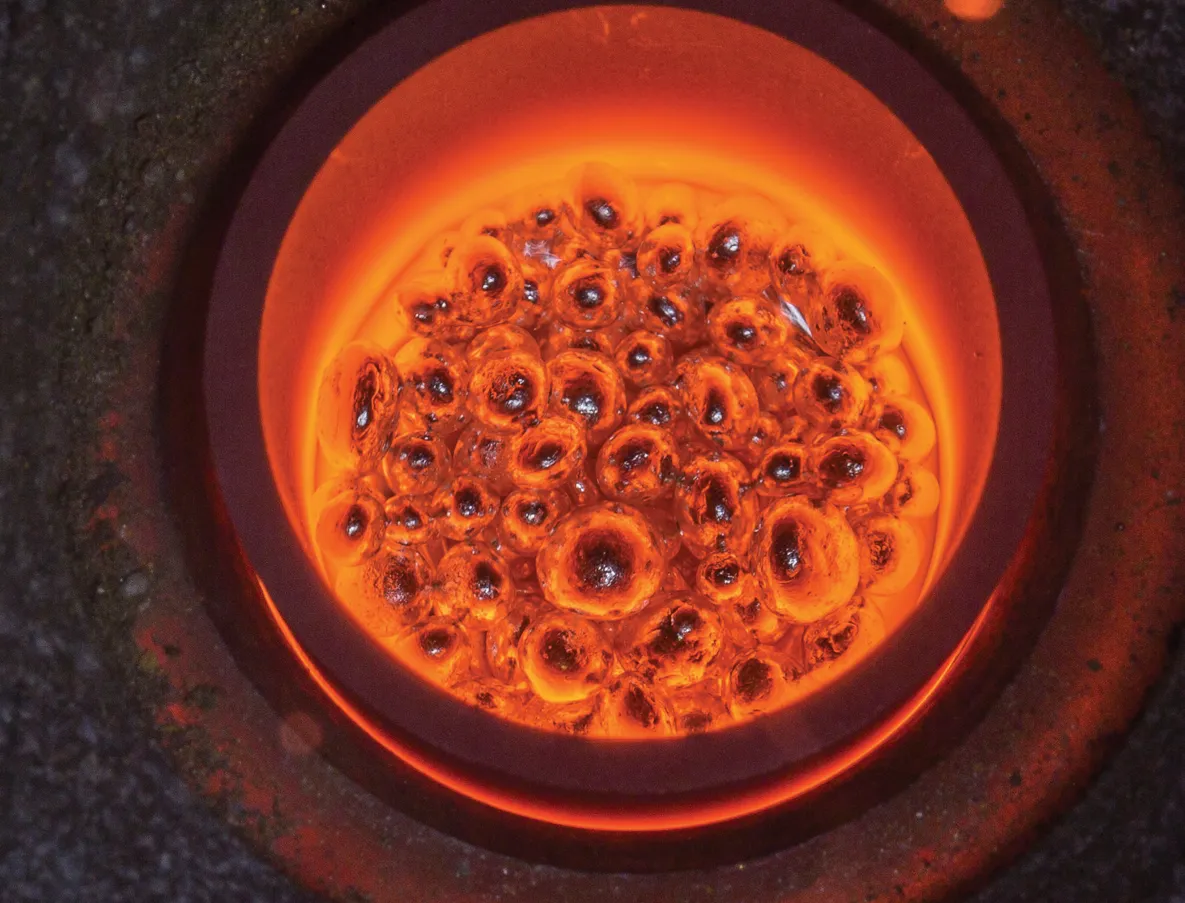

Creating foldable displays, advancing medical innovations, or giving new life to precious metals – at Heraeus, we empower our customers to stay ahead of the curve. As a family-owned global technology leader, we take pride in being the invisible force driving innovation. Whether in production, research, sales, or administration, we deliver world-class quality across key industries: Metals & Recycling, Healthcare, Semiconductor & Electronics, and Industrials. With a strong global presence, including a significant footprint in the United States, Heraeus employs approximately 16,400 people across 40 countries, all dedicated to shaping the future of technology and industry.

Your role and responsibilities

- Summary – As Maintenance Mechanic (Electro-Mechanical/Automation), you ensure assigned machines are fully operational and production ready so production output and quality standards are maintained for the weekend shift. Maintain building mechanical equipment and systems.

- Ensure operation of machinery and mechanical equipment by completing preventive maintenance on production machines, components, and tools, which include but are not limited to: Engines, motors, pneumatics, and conveyor systems.

- Troubleshoot, diagnose and repair problems with oven systems, induction furnaces, and automated/semi-automated manufacturing machinery ensuring production readiness.

- Minimize downtime by training and informing production workers of routine preventive maintenance techniques; monitoring compliance.

- Follow diagrams, sketches, operations manuals, manufacturer’s instructions, and engineering specifications, and troubleshoot and resolve malfunctions.

- Locate sources of problems by observing mechanical devices in operation, listening for problems, and using precision measuring and testing instruments.

- Remove defective parts by dismantling devices using hoists, cranes, and hand and power tools. Examine form and texture of parts, determine changes in dimensional requirements of parts by inspecting used parts with rules, calipers, micrometers and other measuring instruments.

- Inspect, maintain, repair, and replace building mechanical and electrical systems.

What is required for this role

- 5 years of maintenance mechanic experience in a manufacturing environment OR a 2-year degree in industrial maintenance (or similar) and 3 years of maintenance mechanic experience in a manufacturing environment.

- Knowledge of the principles of electricity and PLC controls, mechanics, pneumatics, hydraulics, switch gears, transformers, and power distribution.

- Can troubleshoot and repair PLCs (Siemens and Schneider drives and controls) servos, variable frequency drives.

- Forklift experience and able to be forklift certified.

- Excellent verbal and written communication skills; able to effectively communicate through email correspondence.

- Able to work independently, with little supervision as well as in a team environment.

- Able to work 2:30 p.m. to 12:30 a.m., Monday through Thursday. Must be able to complete initial training on 1st Shift (4, 10s or 5, 8s).

- Must be able to successfully pass a pre-employment drug screen, lift evaluation, and criminal background check.

-

Featured Jobs

Related jobs

- Warehouse Assistant Cartago, Costa Rica Warehouse Assistant

- Sintering Operator (WE) Chandler, United States Sintering Operator (WE)

- CMI Buford, United States CMI

- CMI Buford, United States CMI

- Human Resources Generalist Saint Paul, United States Human Resources Generalist

Related Content

-

What drives us

Innovations are part of our DNA.

-

Who we are

Our actions have been aimed at future generations since 1660.

-

Our Stories

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrudx

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

What we do

Our expertise revolves around materials.

-

Header Lorem Ipsum

Lorem ipsum dolor sit amet, consec tetur adipiscing ut enim ad minim veniam, quis nostrud

-

Careers at Heraeus: Great reasons to start your job

Discover your career opportunities at Heraeus. Learn why Heraeus is a secure and attractive employer for starting your career.

-

Career entry? Yes!

You’re looking forward to the future. So are we. Start your journey with us!

-

Work experience? Yes!

The Heraeus team wants to move forward. So do you. Discover our job opportunities!